How To Get Rid Of Acetaldehyde In Beer

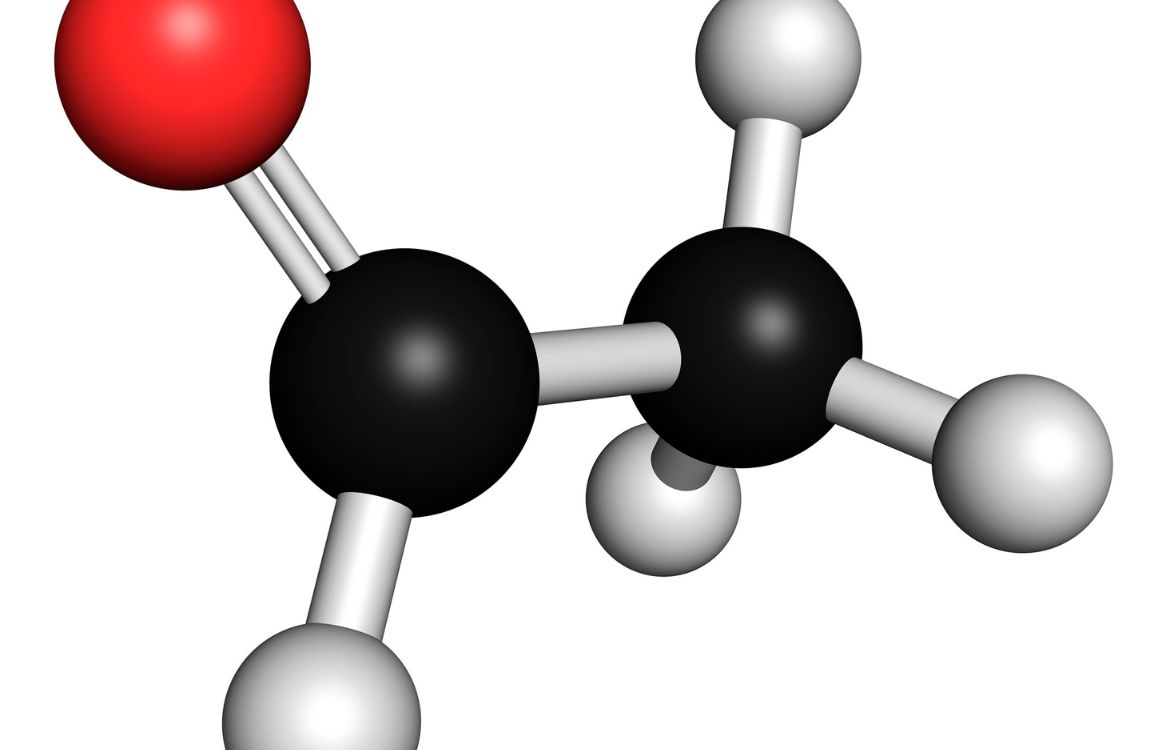

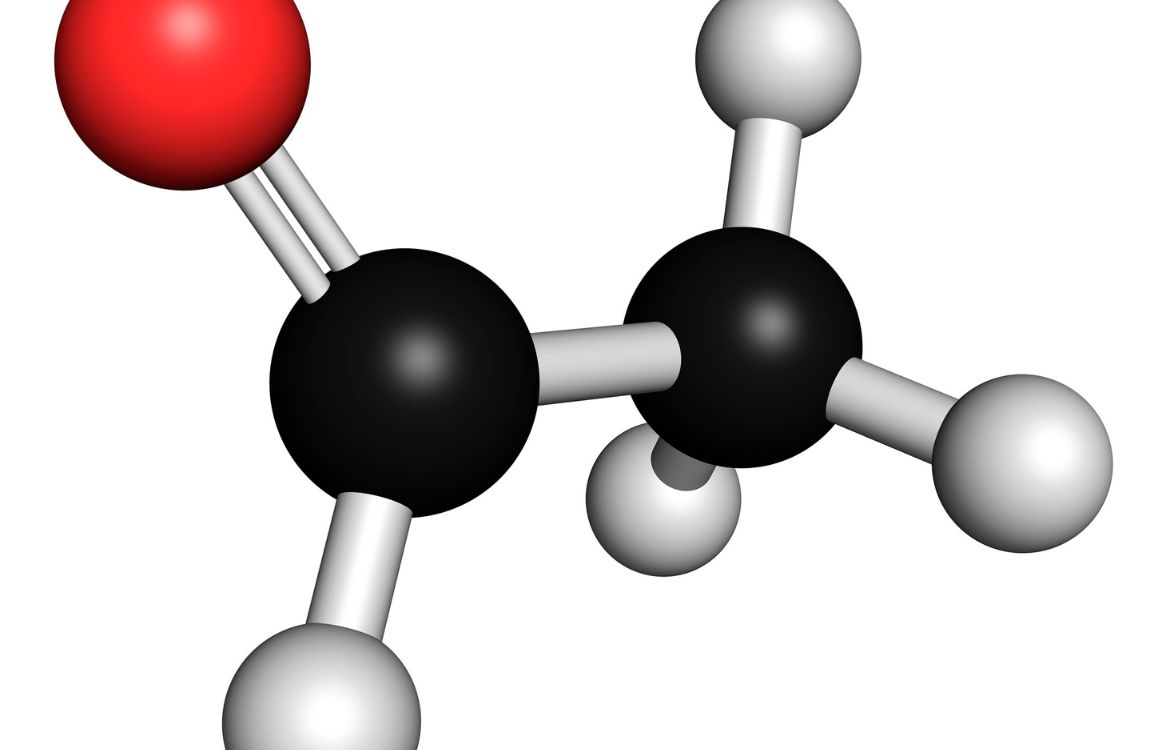

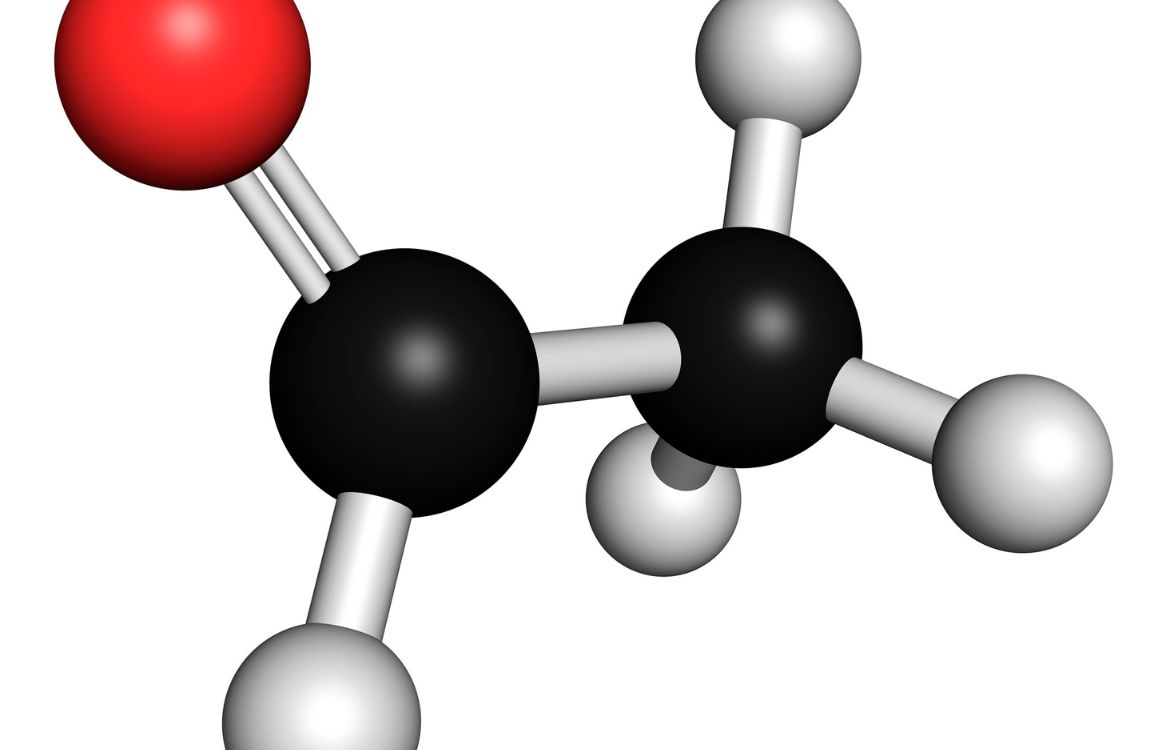

How To Get Rid Of Acetaldehyde In Beer What is Acetaldehyde in Beer?

Acetaldehyde is a naturally occurring chemical compound found in beer. It’s the byproduct of fermentation, and it has a sharp, cider-like flavor that can overtake the delicate nuances of many beers. While there is some debate about what level of acetaldehyde is acceptable when it comes to flavor, excessive amounts can lead to an off-putting harshness in finished beer.

Identifying Acetaldehyde in Beer

As a homebrewer, how can you tell if there’s too much acetaldehyde in your beer? The most common way to identify the presence of acetaldehyde is with taste testing. Once you become familiar with good beer flavor, you will be able to detect when acetaldehyde has become a problem in your beer. Another way to test for acetaldehyde is with a chemical test, which involves a solution of ferrous sulfate, and allows you to detect the presence of acetaldehyde in your beer.

Controlling Acetaldehyde in Beer

Controlling acetaldehyde in beer involves controlling the fermentation and maturation processes. One way to do this is to take the time to allow your fermentation to finish properly, this allows the yeast to clean up the acetaldehyde as part of the finishing process. You can also use a yeast nutrient to encourage yeast fermentation and help keep it healthy throughout the process. To ensure a proper maturation process, invest in an accurate thermometer and keep an eye on fermentation temperatures.

Vortex Oxygenation

Vortex oxygenation is another method to help reduce the amount of acetaldehyde in beer. This process introduces oxygen into the brew, and helps the yeast to stay healthy, which can help reduce the amount of acetaldehyde. Be sure to use an oxygenation system designed for homebrewing, and follow the instructions for proper use.

Temperature Control

Temperature control, particularly during the fermentation stage, can also help reduce the amount of acetaldehyde in your beer. Keeping the fermentation temperature on the cooler side of the recommended range, usually 65- 70°F, will not only help keep acetaldehyde production to a minimum, but can also help to impart a crisp, refreshing quality to the finished beer.

Wet Hopping

Wet hopping is an effective method to reduce the amount of acetaldehyde in beer. This method involves adding hop cones directly to a fermenting beer, and has been found to effectively reduce the presence of acetaldehyde. The hops act as a natural preservative, and also helps to impart flavor and aroma to the finished beer.

Cold Crashing and Clarification

Finally, cold crashing and clarification can help to reduce the presence of acetaldehyde. These processes help to settle out particles and solids in the beer, which in turn can help to reduce the sulfur compounds that contribute to the presence of acetaldehyde. Again, keeping temperatures on the cooler side can help with this process, and will help to enhance the crisp, refreshing quality of the beer.

Conclusion

Acetaldehyde in beer can be an unpleasant flavor, and one that can affect the overall balance and quality of brews. Fortunately, there are steps you can take to reduce or eliminate this flavor from your beer. During the brewing process, be sure to ferment properly, take accurate temperature measurements, add hops, and cold crash and clarify to reduce the presence of acetaldehyde. Don’t forget that taste testing is a key part of the process, and using the right products, like yeast nutrients and oxygen systems, will help to ensure a balanced, flavorful beer.

How To Get Rid Of Acetaldehyde In Beer

How To Get Rid Of Acetaldehyde In Beer  How To Get Rid Of Acetaldehyde In Beer

How To Get Rid Of Acetaldehyde In Beer

Post a Comment for "How To Get Rid Of Acetaldehyde In Beer"